Membrane Systems

How it works

In the construction process, when a building has been framed in it’s entirety, that is the best window of opportunity for vinyl to be installed as a base to the buildings membrane and envelope.

Measurements are made and an inspection of the deck is given to insure the best possible results for installation and interfacing with the building envelope.

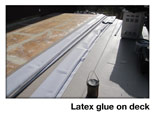

The deck surface is ground, the deck is flashed with wall flashing and drip edge to give a solid finishing edge. Then patched to smooth out inconsistencies.

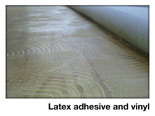

Vinyl is installed in a manner which best compliments the deck. (least amount of seams. It is adhered to a prepared surface of either wood or concrete. The vinyl is heat welded on all seams making the deck completely waterproof.

Doors can be installed after vinyl or before vinyl. It is best to carefully follow the door manufacturers installation guide. Vinyl can be adhered to the bottom of a doorframe and the caulked to add an extra level of redundancy to the vinyl membrane.

Once the Vinyl is installed, the envelope of the buildings exterior can be installed. In the places where the exterior envelope covers the vinyl, the vinyl sits as a redundancy to repel water should the building envelope become compromised.

Sustainability Considerations

As part of a vegetative, cool roof system or Building Re-use, vinyl membranes can be considered for LEED points. The reflectance of the mid range to lighter color, roof grade vinyl is useful in lowering the overall temperature and weight of a roof.

Using vinyl in roof grade application reclaims useable space on flat roof buildings and presents significant opportunities for additional building use, adding tangible value.